- Home

-

- TF Integrated Workstation

- TT Integrated Station

- TS Single-Person Station

- TO Single-Person Station

- Advanced Office Table

- Manager Table

- Odette Conference Table

- Lifting White Board

- Lifting Podium

- Working Port

- Zen Standing Desk

- Lifting Coffee Table

- Home Standing Desk

- Nature Standing Desk

- Invictus Gaming Desk

- Study Desk

-

-

- Electric Hospital Bed

- Image Equipment

- Examination Bed/Clinic Bed

- Operation Table and Chair

- Infant Incubator

- Independent Weighing System

- Home Care Bed

- Patient Lift

- Wheelchair

- Toilet Lift

- Bath Lift

- Shower Trolley

- Smart Rollator Walker

- Ophthalmic Workstation

- Treatment Chair

- Facial Chair

- Traction Table

- Massage Chair

- OT Training Equipment

- Stand-up Application

- Rehabilitation Robot

-

-

- Photovoltaic Application

- Photothermal Application

- Energy Storage Container

- Tractor

- Seeder

- Fertilizer Spreader

- Harvester

- Rotary Cultivator

- Climate Control System

- Automatic Feeding System

- Excavator

- High Altitude Work Platform

- Garbage Truck

- Street Sweeper

- AMR Automated Guided Vehicle (AGV) and Autonomous Mobile Robot (AMR)

- Forklift Accessories

- Palletizing Collaborative Robots

- Packaging Machine

-

-

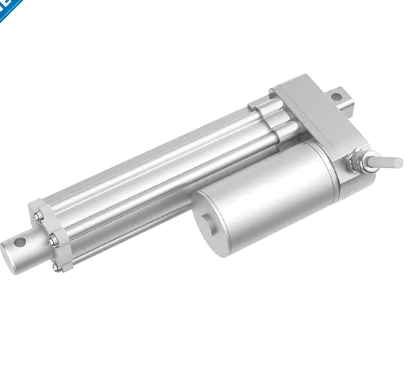

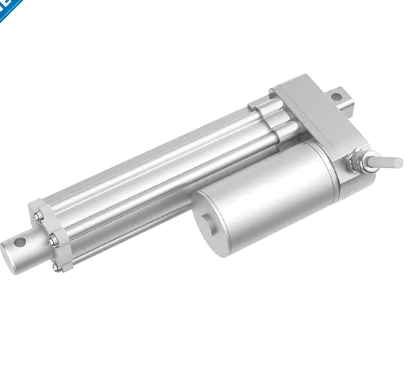

Electric Linear Actuator Applications And Guidelines

Views: 0 Author: Site Editor Publish Time: 2024-12-10 Origin: Site

Electric linear actuators are used to convert rotary motion into linear motions by driving a gear or screw system with an electric motor. These actuators are used widely in robotics, automation, industrial equipment, and other fields. They are highly precise and efficient in their control and can perform high-precision movements within a small space.

Electric linear actuators are becoming more popular in modern equipment due to technological advancements, particularly in the automation, intelligent equipment and medical fields. Electric linear actuators are used in many systems due to their efficiency, precision control, and low maintenance. They also meet the requirements for miniaturization and fast response.

Working principle of electric linear actuator

Basic Principle

Electric linear actuators work on the principle that an electric motor generates rotary motion and then converts it to linear reciprocating motion using a screw or gear. The motor rotates the gear or screw, which then drives the piston or nut to move along the rail guide to achieve linear displacement. This mechanism is used for precise motion control in automation, robots, and precision equipment.

Components and Functions

Motor: A device that converts electrical energy into rotational motion.

Nut and Screw: Converts rotary motion to linear motion.

Guide rail: This is a guide that guides the nut, piston or sprocket to ensure accuracy in linear motion.

Limit switch: This is used to limit the movement of the motor by setting the maximum and minimum stroke values.

Feedback sensor: This sensor monitors the position of actuators and gives accurate feedback signals for controlling the movement.

Application areas of electric linear actuators

1. Industrial Automation

Electric linear actuators are used widely in industrial automation, including production lines and robotic arms. Electric actuators are able to perform handling, assembly, and testing tasks with precision on automated production lines. The use of electric actuators in robotic arms allows robots to perform complex production tasks with greater precision and flexibility.

2. Medical Equipment

In the field of medical equipment, electric linear actuators are widely used in bed adjustment, medical device positioning and minimally invasive surgical tools. Electric actuators provide precise and smooth movement to ensure the reliability of medical equipment and the comfort of patients. For example, the adjustment system of electric beds relies on actuators to achieve precise adjustment of the bed angle and improve the patient experience.

3. Home Automation

In smart homes, electric linear actuators are used in electric curtains, adjustable beds, smart tables and other equipment to provide a comfortable living environment through precise control. Actuators can achieve automatic adjustment and improve the convenience of users' lives.

4. Automotive Industry

In the automotive industry, electric linear actuators are widely used in seat adjustment, window lifting systems, etc., providing convenient automatic adjustment functions. Its high efficiency, low noise and precise control significantly improve the comfort and functionality of the vehicle.

Advantages and challenges of electric actuators linear

1. Advantages

Electric linear actuators have the advantages of high-precision control, low noise, easy integration and low maintenance requirements. They are able to provide stable and accurate linear motion in a variety of applications and are suitable for occasions requiring high precision and reliability.

2. Challenges

However, electric linear actuators may face load capacity and speed limitations in some applications. For tasks that require large thrust or fast movement, the performance of the actuator may not be sufficient to meet the requirements.

Criteria for selecting electric linear actuators

1. Selection factors

When selecting an electric linear actuator, several key factors need to be considered. Thrust determines the maximum load that the actuator can withstand, and the selection needs to be matched according to the actual load requirements. The stroke determines the maximum movement distance of the actuator to ensure that the displacement requirements of the application are met. Speed affects the response time and efficiency of the movement and adapts to different operating requirements.

The size must be compatible with the equipment space and structure to ensure effective use of the installation space. The power should match the power supply capacity of the power supply to avoid overload. Durability is related to the service life of the actuator, especially in high-frequency or harsh environments.

2. Installation and commissioning

When installing an electric linear actuator, first determine the installation location and secure the actuator. When connecting the controller, ensure that the power supply and cable match, and the controller settings must be consistent with the working requirements of the actuator. Then debug and check the stroke, speed and load capacity to ensure smooth operation. During the debugging process, it is necessary to adjust the limit switches and set the appropriate working range.

Conclusion

Electric linear actuators are essential for precise, controlled linear motion in various applications, including automation, robotics, medical equipment, and home systems. They offer advantages like high precision, low noise, and easy integration into existing systems. When selecting reliable and high-performance electric linear actuators, we recommend JIECANG, a trusted leader in actuator technology, offering durable and innovative solutions for diverse needs.

Frequently Asked Questions

1.How do electric linear actuators work?

Electric linear actuators convert rotational motion of an electric motor to linear motion. The motor drives either a gear or screw mechanism that moves a nut along a rail in a precise straight line. This mechanism can be used for a variety of applications that require precise, controlled movement.

2.How does an electric linear actuator work?

Electric linear actuators work by converting the rotational motion of an electric motor to linear movement. The motor drives the lead screw or gear, which then moves a nut, piston, or guide rail along a guide rail, creating precise straight line motion. This setup provides precise control of speed, force and position. It is ideal for automation, robotics and medical devices.

3.Why use electric linear actuators?

Electric linear actuators have been used in automated systems for years because of their reliability, precision and simplicity. They can provide controlled, smooth motion without external sources such as air or hydraulics. They are ideal for robotics, medical devices and industrial automation.

4.How does an electric linear actuator work?

Electric linear actuators work by converting rotational motion into linear motion using a gear or lead screw system. The motor drives a screw that moves a piston or nut along a track to create straight-line motion. This mechanism allows precise control of force, speed, and position. It is suitable for many applications, including automation, robotics and medical devices.

Related Products

QUICK LINKS