In recent years, with the continuous development of photovoltaic and photothermal power generation technologies, solar tracking systems are more and more used in power station construction. As the key auxiliary equipment of the tracking system, the electric actuator plays an important role in it.How

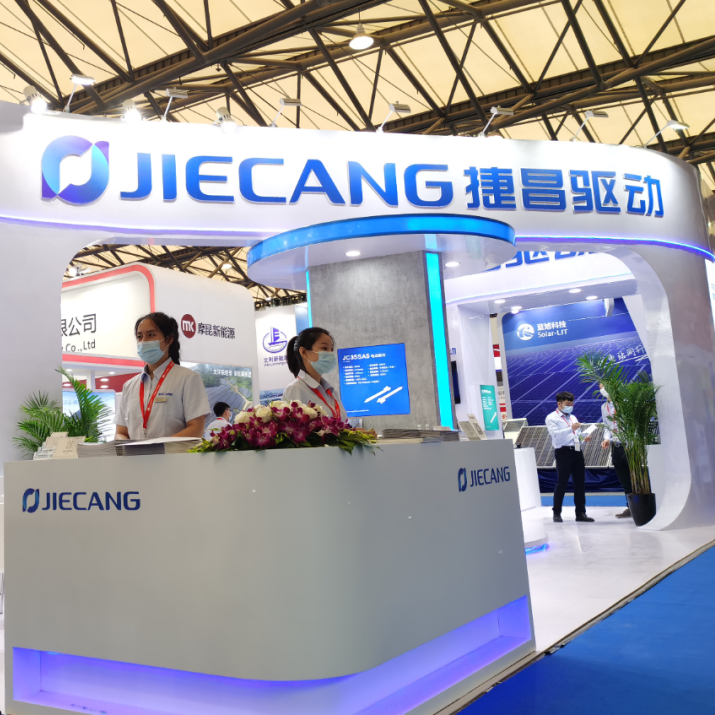

From June 3rd to 5th, 2021, the 15th (2020) International Solar Photovoltaic and Smart Energy Conference and Exhibition of SNEC will be held in Shanghai New International Expo Center (Pudong).Jiecang appeared at booth 335 in Hall E3, and launched smart actuator solutions in the field of new energy (

Today (October 27), the 15th Asian Solar Photovoltaic Innovation Cooperation Forum and Exhibition opened in Hangzhou International Expo Center (G20 Summit Pavilion), and Jiecang intelligent industrial environment drive system products were unveiled.During the two-day exhibition, we will meet you in

When it comes to automating motion in various applications, the linear actuator 12V is a popular choice due to its versatility, reliability, and ease of use. However, to achieve optimal performance from your 12V linear actuator, selecting the right controller is crucial. The controller not only gove

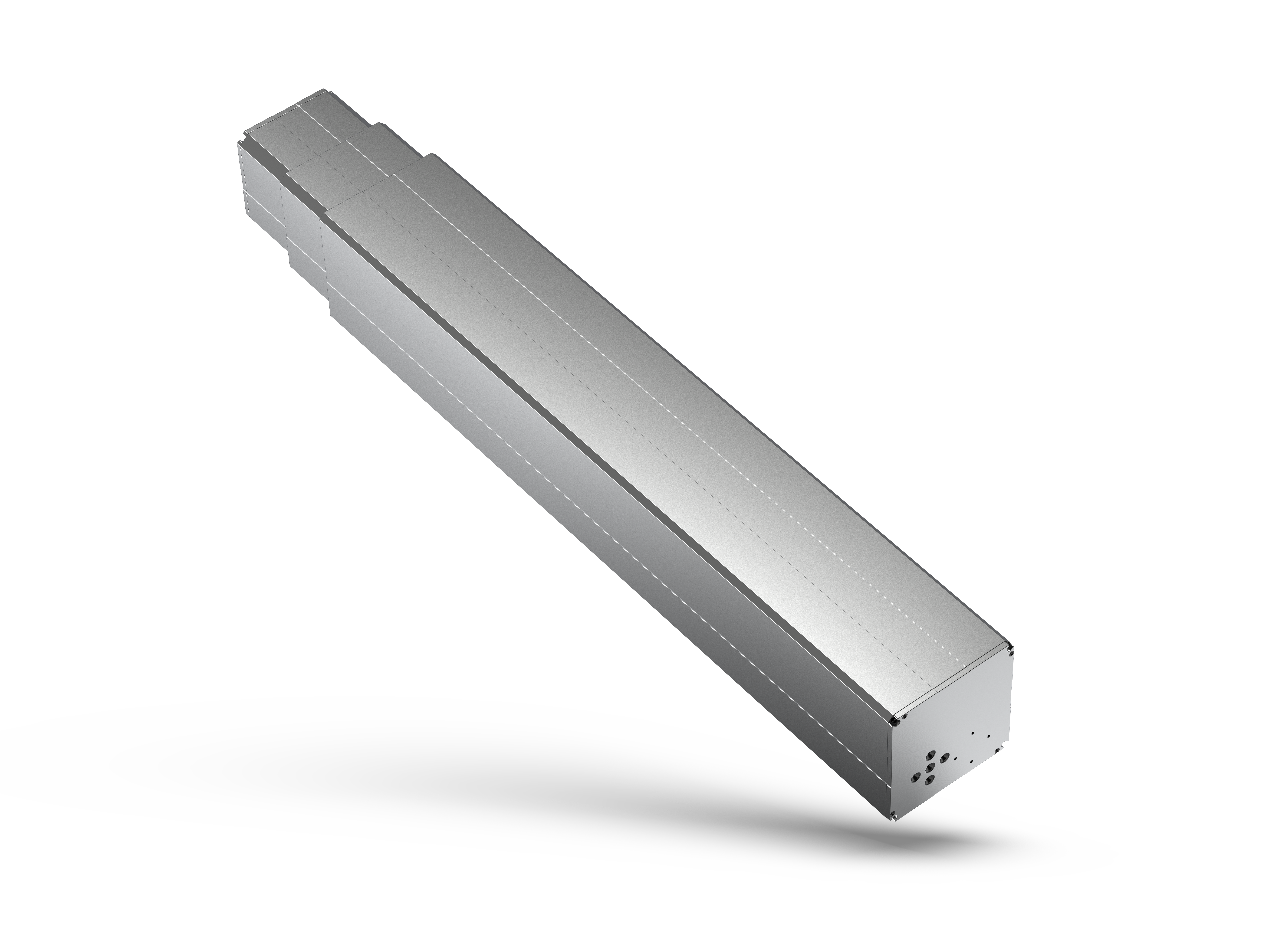

JIECANG's JC35FA2 electric actuator revolutionizes material handling by enhancing energy efficiency, precision, and reducing maintenance costs.

How can we ensure the safe operation of ventilation systems in these conditions? With 24 years of expertise, JIECANG introduces the JC35FA17 explosion-proof electric actuator, tailored for the energy storage industry to provide an advanced safety solution.

JIECANG partnered with a leading sports brand to enhance their high-end indoor cycling bikes. We developed the JC35FA30 electric actuator, delivering precise resistance adjustment for an optimized workout experience.

Discover how our linear actuators are transforming automated feeding systems in modern farming. By enhancing efficiency, ensuring precise feeding control, and reducing maintenance, JIECANG actuators help farmers optimize operations.