- Home

-

- TF Integrated Workstation

- TT Integrated Station

- TS Single-Person Station

- TO Single-Person Station

- Advanced Office Table

- Manager Table

- Odette Conference Table

- Lifting White Board

- Lifting Podium

- Working Port

- Zen Standing Desk

- Lifting Coffee Table

- Home Standing Desk

- Nature Standing Desk

- Invictus Gaming Desk

- Study Desk

-

-

- Electric Hospital Bed

- Image Equipment

- Examination Bed/Clinic Bed

- Operation Table and Chair

- Infant Incubator

- Independent Weighing System

- Home Care Bed

- Patient Lift

- Wheelchair

- Toilet Lift

- Bath Lift

- Shower Trolley

- Smart Rollator Walker

- Ophthalmic Workstation

- Treatment Chair

- Facial Chair

- Traction Table

- Massage Chair

- OT Training Equipment

- Stand-up Application

- Rehabilitation Robot

-

-

- Photovoltaic Application

- Photothermal Application

- Energy Storage Container

- Tractor

- Seeder

- Fertilizer Spreader

- Harvester

- Rotary Cultivator

- Climate Control System

- Automatic Feeding System

- Excavator

- High Altitude Work Platform

- Garbage Truck

- Street Sweeper

- AMR Automated Guided Vehicle (AGV) and Autonomous Mobile Robot (AMR)

- Forklift Accessories

- Palletizing Collaborative Robots

- Packaging Machine

-

-

How to Choose a Suitable Linear Actuator 12V Controller ?

Views: 0 Author: Site Editor Publish Time: 2024-08-23 Origin: Site

When it comes to automating motion in various applications, the linear actuator 12V is a popular choice due to its versatility, reliability, and ease of use. However, to achieve optimal performance from your 12V linear actuator, selecting the right controller is crucial. The controller not only governs the actuator's operation but also ensures smooth, precise, and safe movement in your specific application. In this article, we will guide you through the key considerations to help you choose a suitable controller for your linear actuator 12V.

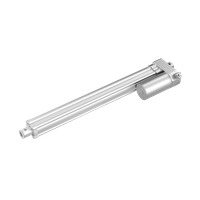

Understanding the Basics of a Linear Actuator 12V

Before diving into the selection process, it's essential to understand what a linear actuator 12V is and how it functions. A 12V linear actuator is an electromechanical device that converts electrical energy into linear motion. It operates on a 12-volt power supply, making it ideal for various low-voltage applications, including automotive systems, home automation, robotics, and industrial machinery. The actuator typically consists of a motor, gearbox, lead screw, and other components that work together to produce controlled linear movement.

Factors to Consider When Choosing a Controller for a Linear Actuator 12V

Selecting the right controller for your linear actuator 12V involves considering several important factors. Each of these elements plays a critical role in determining the performance and suitability of the controller for your specific application.

1. Voltage Compatibility

The most fundamental aspect to consider is ensuring that the controller is compatible with a 12V power supply. Since your actuator operates on 12 volts, the controller must be designed to handle this voltage to ensure seamless integration and operation. Controllers designed for different voltages (such as 24V or 48V) are not suitable for a 12V linear actuator and could lead to malfunction or damage.

2. Control Options and Features

Different applications require different levels of control. Some basic controllers offer simple forward and reverse functions, while more advanced models provide features like speed control, position feedback, and programmable limits. Depending on your needs, you may require a controller with specific features:

Speed Control: Allows you to adjust the speed of the actuator's movement, which can be crucial in applications requiring precise motion control.

Position Feedback: Enables the controller to monitor the exact position of the actuator, providing higher accuracy in applications like robotics or automated machinery.

Programmable Limits: Helps set the maximum and minimum extension points, preventing over-extension or retraction that could damage the actuator.

3. Load Capacity and Current Rating

The controller must be able to handle the electrical current required by your linear actuator 12V. This is especially important if your actuator is driving a heavy load or requires high torque. Check the actuator’s specifications for the current draw under load and ensure that the controller's current rating matches or exceeds this requirement. Overloading the controller can result in overheating, reduced efficiency, or even failure.

4. Control Interface

Consider how you intend to operate the actuator. Controllers can be operated manually via switches, remotely through wireless devices, or even integrated into automated systems using software interfaces. The choice of interface should align with your application’s operational needs:

Manual Control: Ideal for straightforward applications where direct user input is required.

Remote Control: Suitable for applications where the actuator needs to be operated from a distance or in hard-to-reach areas.

Automated Control: Perfect for complex systems where the actuator is part of a larger automation process controlled by a computer or microcontroller.

5. Environmental Considerations

The operating environment plays a significant role in the selection of a suitable controller. If your linear actuator 12V will be used in harsh conditions, such as extreme temperatures, high humidity, or exposure to dust and water, you’ll need a controller with appropriate environmental protection ratings. Look for controllers that are rated for the specific conditions your application will encounter, such as IP-rated enclosures for water and dust resistance.

How to Choose the Right Controller for Your Application ?

Once you’ve considered the above factors, you can narrow down your options and select the controller that best suits your needs. Here are some practical steps to guide you:

Evaluate Your Application Requirements: List all the features and functionalities you need from the controller based on your application’s demands.

Compare Different Models: Research various controller models that meet your criteria. Compare their specifications, features, and customer reviews to determine which one offers the best value.

Consult with Experts: If you’re unsure about your choice, consult with manufacturers or industry experts who can provide guidance based on their experience and knowledge of the latest technologies.

Test Before Finalizing: If possible, test the controller with your 12V linear actuator in a controlled environment to ensure compatibility and performance before full-scale implementation.

Advantages of JIECANG Linear Actuators

When it comes to high-quality linear actuators, JIECANG stands out as a leading provider in the industry. JIECANG's 12V linear actuators are known for their durability, precision, and adaptability across various applications. Here are some advantages of choosing JIECANG linear actuators:

Advanced Technology: JIECANG linear actuators incorporate the latest advancements in motor technology, ensuring smooth and efficient operation with minimal noise.

Customization Options: JIECANG offers a wide range of customization options, allowing customers to tailor actuators to their specific needs, whether it's for speed, stroke length, or mounting configurations.

Reliable Performance: Designed to handle demanding conditions, JIECANG actuators are built with high-quality materials and components, providing reliable and long-lasting performance.

Global Support: With a strong customer support network, JIECANG ensures that clients receive the assistance they need, from product selection to post-installation support.

Choosing the right controller for your linear actuator 12V is essential for achieving optimal performance and efficiency. By carefully considering the factors outlined in this article, you can make an informed decision that meets your application’s specific needs. For those seeking top-tier performance and reliability, JIECANG's range of 12V linear actuators is a smart choice, backed by cutting-edge technology and comprehensive customer support.

QUICK LINKS