- Home

-

- TF Integrated Workstation

- TT Integrated Station

- TS Single-Person Station

- TO Single-Person Station

- Advanced Office Table

- Manager Table

- Odette Conference Table

- Lifting White Board

- Lifting Podium

- Working Port

- Zen Standing Desk

- Lifting Coffee Table

- Home Standing Desk

- Nature Standing Desk

- Invictus Gaming Desk

- Study Desk

-

-

- Electric Hospital Bed

- Image Equipment

- Examination Bed/Clinic Bed

- Operation Table and Chair

- Infant Incubator

- Independent Weighing System

- Home Care Bed

- Patient Lift

- Wheelchair

- Toilet Lift

- Bath Lift

- Shower Trolley

- Smart Rollator Walker

- Ophthalmic Workstation

- Treatment Chair

- Facial Chair

- Traction Table

- Massage Chair

- OT Training Equipment

- Stand-up Application

- Rehabilitation Robot

-

-

- Photovoltaic Application

- Photothermal Application

- Energy Storage Container

- Tractor

- Seeder

- Fertilizer Spreader

- Harvester

- Rotary Cultivator

- Climate Control System

- Automatic Feeding System

- Excavator

- High Altitude Work Platform

- Garbage Truck

- Street Sweeper

- AMR Automated Guided Vehicle (AGV) and Autonomous Mobile Robot (AMR)

- Forklift Accessories

- Palletizing Collaborative Robots

- Packaging Machine

-

-

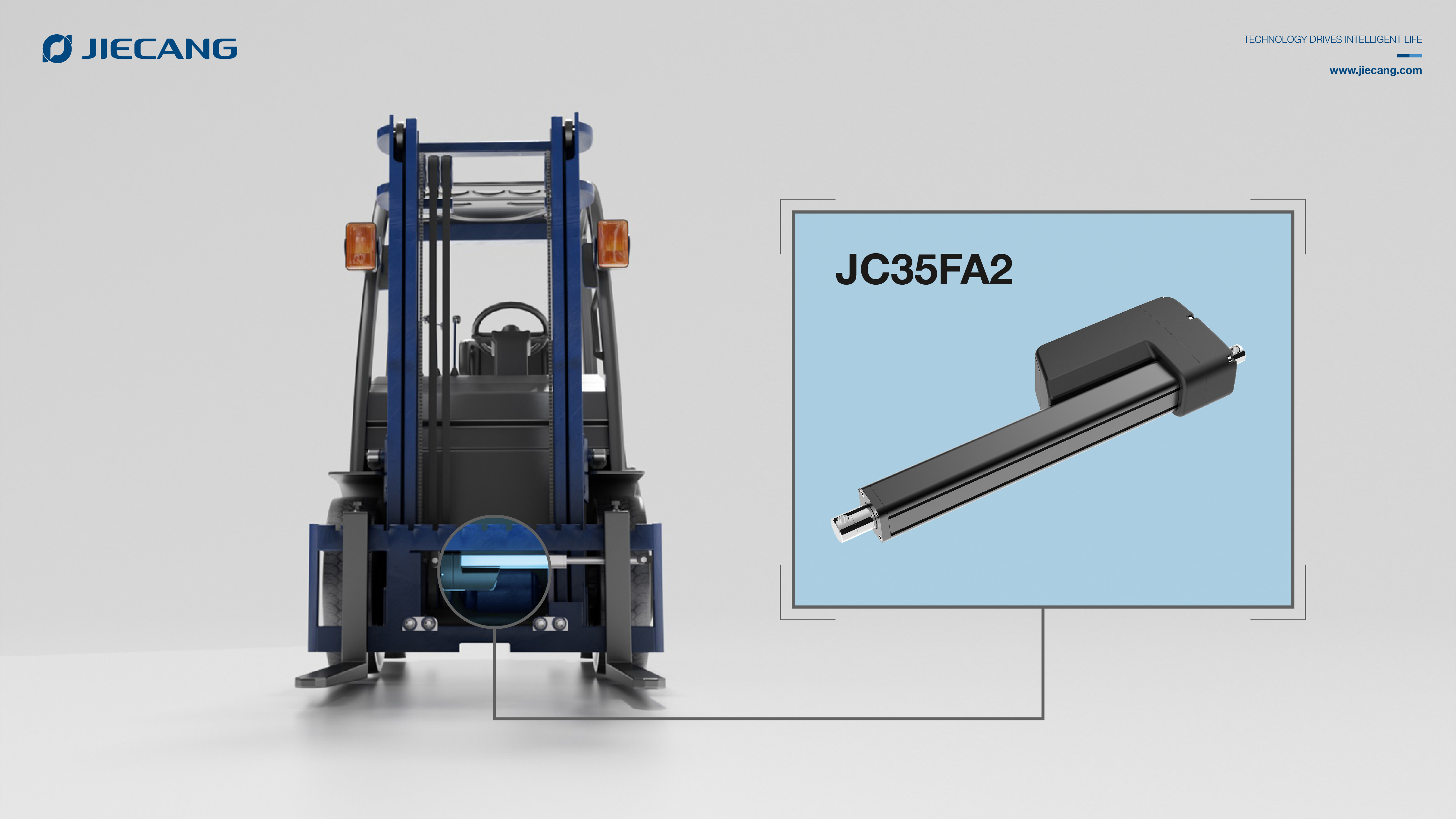

Why JIECANG's JC35FA2 Is Must-Have Electric Actuator for Your Side Shifters

Views: 0 Author: Site Editor Publish Time: 2024-08-26 Origin: Site

The increasing emphasis on efficiency and sustainability in the industrial sector has driven innovation in material handling and logistics equipment. JIECANG's JC35FA2 Electric Actuator offers a revolutionary alternative to traditional hydraulic side shifters, delivering superior performance, energy efficiency, and ease of maintenance.

Challenges of Traditional Hydraulic Side Shifters

Hydraulic side shifters, which move forklift tines horizontally, are widely used but come with notable drawbacks:

High Energy Consumption: Hydraulic systems lose significant energy during power transfer, lowering overall efficiency.

Complex Maintenance: Hydraulic systems are prone to oil leaks due to prolonged use, which is particularly problematic in industries with strict cleanliness standards, such as food and pharmaceuticals. Consequently, maintenance often requires skilled technicians, leading to increased operational costs.

Limited Precision: The control accuracy of hydraulic systems is often insufficient for applications that require high precision, such as automated guided vehicles (AGVs).

Advantages of the JC35FA2 Electric Actuator

To address these challenges, JIECANG introduced the JC35FA2 electric actuator, providing a fresh solution for material handling equipment that overcomes the limitations of traditional hydraulic systems.

Energy Efficiency: Driven by an electric motor, the JC35FA2 converts rotary motion into linear movement with minimal energy loss, dramatically improving system efficiency. This is particularly beneficial for battery-powered equipment like AGVs, as it extends operating time between charges and reduces overall energy consumption.

Low Maintenance and Eco-Friendly: The waterpoof JC35FA2 eliminates the risk of oil leaks, ensuring a cleaner, more sustainable solution. This makes it ideal for industries like food processing and pharmaceuticals, where equipment hygiene is critical. Additionally, the system’s reduced maintenance needs increase uptime, cutting down on costly repairs and interruptions.

Precise Independent Control: Integrated sensors enable precise monitoring and adjustment of horizontal movement. Using the CANopen protocol, the JC35FA2 transmits critical data—such as position, speed, and diagnostics—directly to automated systems, allowing for highly accurate positioning and smoother operation, which helps prevent product damage and operational errors.

Reducing Overall Operating Costs: Thanks to its high efficiency and ease of maintenance, the overall operating costs have been significantly reduced. Businesses can lower operational costs by reducing energy consumption, while also enhancing productivity by minimizing maintenance frequency and downtime. Additionally, the integrated sensor design in OEM manufacturing reduces the need for extra sensors, further lowering production costs.

Conclusion

As automation and smart manufacturing continue to evolve, the demand for energy-efficient, precise, and low-maintenance equipment will only increase. JIECANG's JC35FA2 Electric Actuator represents the cutting edge of this transition, offering a powerful, clean, and highly accurate solution for material handling and logistics applications. It is clear that electric side shifters, powered by actuators like the JC35FA2, are set to replace hydraulic systems as the industry standard, driving forward the future of smart logistics.

QUICK LINKS